Aluminum gravity casting converting to high pressure die casting

Aluminum gravity casting can also be referred to aluminum metal mold gravity casting or permanent mold casting. It seems to aluminum high pressure die casting, but they are actually distinguishing. Aluminum gravity casting uses gravity as casting force,while the high pressure die casting use mechanical oil pressure as casting force. Furthermore, aluminum gravity casting can use sand core to achieve concaved features of aluminum castings, but it is not suited for high pressure die casting. Except these main difference, aluminum gravity casting is quite similar to die casting.

During the last three years,Parison has accepted several such converting projects. Our professional engineers team are ready to assist you to convert gravity casting parts to much more precision and mass production preferable high pressure die casting parts .

Aluminum gravity casting technique database

Surface treatment: aluminum gravity cast parts can only be black hard anodized as high pressure die cast parts. Besides it can be suited to other surface treatment like powder coating, electroplating, painting, electrophoresis, and polishing etc.

Heat treatment: aluminum gravity cast parts can also be processed by heat treatment to improve its inner crystal and surface hardness. While high pressure die cast parts can't be heat treated.

Feasible concaved features: aluminum gravity casting process can apply sand cores for concaved features, which is not available for high pressure die casting.

Notes of converting to die casting part

Reduction of mechanical property: Aluminum gravity casting has much higher density than high pressure die casting part, for application of gravity, its inner porosity is not as serious as that of die casting parts. Furthermore aluminum gravity casting can apply heat treatment like T5 and T6, but which can't be applied for high pressure die casting. Before we convert gravity casting to die casting parts, the reduction of mechanical property should be considered carefully.

Necessary design adaptation: Those concaved features of gravity casting may be partially achieved by slide block in die casting process,but generally are infeasible. When gravity castings with sand core application are converted, we always have to redesign even remove such features.

Besides, high pressure die casting can have small draft angle and edge rounds, which can be adapted readily.

Deduction of machining allowance: high pressure die casting process can obtain much precise dimensions than gravity casting. While converting, some tolerances can be achieved by casting process directly, and some extra machining allowance can be saved.

Come to other die casting conversions

Accepting die casting conversion projects

During the last three years,Parison has established two manufacturing factories in the mainland and been expanding our manufacturing capability in non-ferrous metal industry. In the near future, we are to set up aluminum extrusion and cold forging factories in Yangtze River district.

Our professional engineers team engaged in non-ferrous metal manufacturing are ready to assist you in product design, choosing production process and other engineering issues.

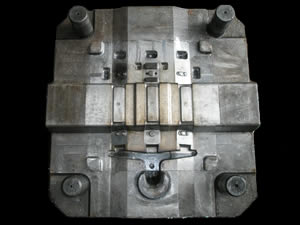

aluminum gravity casting illustration