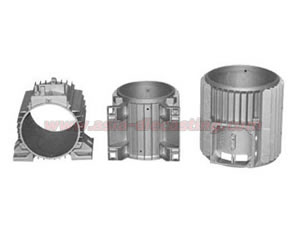

Aluminum die casting motor housing series

Aluminum die cast motor housings are now popular for electrical motor manufacturers. Compared with iron cast motor housings, aluminum die cast ones have many advantages, such as light weight, low noise, low cost and high yield. In western europe, nearly 98% of common motor housings are produced by aluminum die casting process. Because of its large demand of the motor, the aluminum die cast motor housing and head also has a large market.

Parison die casting foundry has been supplying certain types of motor housing and head for several domestic manufacturers and an Italy customer. The various types of die cast motor housings almost cover all our different tonnage machines. Parsion Machinery is planning to set up a motor housing R&D dept. in order to develop our own designed die cast motor housing series.

Advantage of aluminum die cast motor housing

The popularity of aluminum die casting motor housing is certain market trend, because of much of its advantage. Nearly all motor manufacturers have been changing their iron cast motor housing to aluminum die cast ones.

Light weight: because of low weight of aluminum alloy, the die cast motor housing is lighter than common iron cast housings.

Low noise: The aluminum die cast housing can have more flexible design as reduces its noise considerably.

Fine conductivity: Aluminum alloy has fine heat conductivity, as facilitates the whole function of motors.

Low cost: Aluminum alloy is quite cheaper, furthermore the mass production of aluminum die casting process can reduce unit price a lot. Thus an aluminum die cast motor housing can be cheaper than an iron one of same size.

Compared with iron cast motor housing

Iron cast motor housings use sand casting process, which is a labor intensive production process. Its unit price can be much higher than aluminum die cast ones, though its sand casting mold can be much cheaper. Another distinct difference is its low production yield, evan a raw cast iron motor housing can take nearly half hour ( now only large motor housings are still produced by sand casting process ) . The iron cast motor housing is always heavier than aluminum die cast motor ones, and has worse heat conductivity.

However, iron cast motor housing is still used for heavy and large motors, because it will be economical to produce several ones with low investment in sand casting mold, and the sand cast motor can stand much large load than that of aluminum.

FAQ's of aluminum die cast motor housing and head

- why is aluminum die cast motor housing popularer than sand cast ones?

- what is the advantage of aluminum die cast motor housing?

- what is the difference between iron sand cast and aluminum die cast motor housings ?

- What is application of die cast motor housing?