Aluminum and zinc high pressure die casting design

No matter aluminum die casting or zinc die casting, their design is a professional job, requiring rich casting experience and assistance of advanced instrument and software. We have performed teamwork for all of our die casting project. Such team included casting engineer, machining engineer and outsourcing manager and english speaking coordinator. Casting engineer and machining engineer take on the technique job and work out the design of casting and mold. The outsourcing manager will collect necessary information as to other surface finishing, tooling manufacturer and coordinate sub-suppliers to meet production aim. The english speaking coordinator is dedicated to communicate the design and manufacturing detailes with foreign customers.

Aluminum die casting design

Aluminum die casting design includes raw casting design with die casting mold, finish production design involving post machining and other surface finishing such as electroplating, electrophoresis, painting, anodizing and powder coating. Casting design is not a simple and plain working only invloving die casting mold and raw casting. We need to take into consideration every manufacturing steps.for more....

Zinc die casting design

There two kinds of die casting processes available for zinc high pressure die casting. Commonly we cast samll zinc die cast products by hot chamber die casting machine, and larger parts by cold chamber die casting machines. Thus before we start zinc die casting design, we will confirmed with customers which kinds of machine he prefers. Eecept of this issue, the design of zinc die casting is quite the same as that of aluminum die casting.

Die casting design software

- 3-d design software:Solidworks; Pro-engineer,Autodesk inventor

- 2-d design software: AutoCAD

- Handling file formates: igs, stp, step, and any formates can be handled by above softwares

Aluminum gravity casting part converting to die casting part

aluminum gravity casting part used a metal die similar to a die casting mold. The main difference is the casting force they are used. Gravity casting process applies gravity, while aluminum die casting process applies mechanical pressure. Once we convert gravity cast part to high pressure die cast part, the sprue,running and gate systems should be adjusted. And the feature of gravity cast part obtained by sand cores may not be achieved by high pressure die casting process. However, some of such features can be obtained by slide block in die casting process.

Aluminum sand casting part converting to die casting part

Machining part converting to die casting part

Aluminum extrusion part converting to die casting part

Low pressure die casting part converting to high pressure die casting one

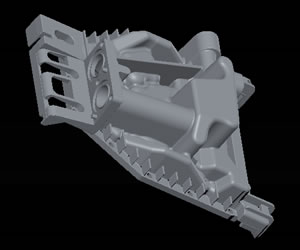

Typical aluminum die casting design

It is a quite complicated aluminum die cast part. There are two through holes should be obtained by slide block, while on its right side, another slide block is used for an air outlet. The back side is obtained by fixed half die, where lots of fins concentrates. The other side is located on moving half die, where concentrated grooves will be machined succeedingly, thus ejector traces can be removed by post machining.